साफ बर्फ बनाम बादल बर्फ

| पहलू | स्पष्ट बर्फ | बादल छाएदार बर्फ |

| उपस्थिति | पारदर्शी, शीशे की तरह साफ. | अस्पष्ट, अशुद्धियाँ हो सकती हैं. |

| बनावट | चिकना, कोई दृश्य बुलबुले नहीं. | फंसी हुई हवा होती है. |

| घनत्व | कोई अशुद्धता के कारण सघन. | हवा की जेब के साथ कम घना. |

| पिघलने की दर | धीमी गति से पिघलता है, लंबे समय तक सर्द. | अशुद्धियों के साथ तेजी से पिघल सकते हैं. |

| सौंदर्य अपील | दृश्य प्रस्तुति को बढ़ाता है. | के रूप में आकर्षक नहीं हो सकता है. |

| कॉकटेल में स्पष्टता | सामग्री दिखाने के लिए आदर्श. | कॉकटेल लुक से अलग हो सकते हैं. |

| गठन प्रक्रिया | स्पष्टता के लिए धीमी गति से ठंड की आवश्यकता है. | जल्दी से गठित, फँसाने वाली हवा. |

| में पसंद किया गया… | उच्च अंत बार, अपस्केल रेस्तरां. | आकस्मिक सेटिंग्स में आम. |

पेय उद्योग में, स्पष्ट और बादल छाए बर्फ के बीच की लड़ाई उपस्थिति से परे है - यह एक पारगमन संवेदी अनुभव के लिए एक खोज है. स्पष्ट बर्फ, इसकी प्राचीन पारभासी के साथ, खानपान में गुणवत्ता के लिए एक प्रतिबद्धता का प्रतीक है. क्रिस्टल क्लियर आइस क्यूब्स प्रीमियम पेय का पर्याय बन गए हैं, पूरे पीने के अनुभव को ऊंचा करना. सावधानीपूर्वक सटीकता के साथ तैयार किया गया, वे खानपान में उत्कृष्टता को फिर से परिभाषित करते हैं. एक क्रिस्टल-क्लियर ग्लास में एक पूरी तरह से तैयार किए गए कॉकटेल की कल्पना करें, निर्दोष बर्फ के टुकड़े से सजी. यह सौंदर्य आकर्षण संरक्षक को पकड़ लेता है’ ध्यान, एक असाधारण पीने के अनुभव के लिए मंच सेट करना. इस कला में महारत हासिल करना स्पष्ट बर्फ के क्यूब्स के पीछे विज्ञान को समझने के साथ शुरू होता है.

क्लियर आइस क्यूब्स के पीछे का विज्ञान

बर्फ के गठन को समझना:

बर्फ निर्माण एक आणविक नृत्य है, और स्पष्टता इसे ठीक से ऑर्केस्ट्रेट करने पर टिका है. ठंड की गतिशीलता महत्वपूर्ण है, त्रुटिहीन स्पष्ट बर्फ क्यूब्स को क्राफ्टिंग के लिए मंच सेट करना.

बादल का कारण बनता है:

घर के फ्रीजर में फ्रीजिंग के कारण पारंपरिक बर्फ के बादल, अशुद्धियों और हवा के बुलबुले फंसना. पूर्णता को प्राप्त करने के लिए इन रहस्यों को उजागर करना आवश्यक है.

अशुद्धता और वायु बुलबुले:

ठंड के दौरान पानी और हवा में घुसपैठ में अशुद्धियों से बादल का परिणाम होता है, बर्फ की स्पष्टता को कलंकित करना. इसे पार करने के लिए, उनके स्रोत पर अशुद्धियों को खत्म करना अनिवार्य है.

धीमी ठंड समाधान:

बादल के लिए एंटीडोट जानबूझकर है, धीमी जमाव. यह सावधानीपूर्वक दृष्टिकोण अशुद्धियों और हवा के बुलबुले के लिए कमरे को कम करता है, प्रत्येक क्यूब सुनिश्चित करना एक निर्दोष जमे हुए कृति के रूप में उभरता है.

औद्योगिक बर्फ मशीनें बनाम. परंपरागत फ्रीजर

| पहलू | औद्योगिक बर्फ मशीनें | परंपरागत फ्रीजर |

| लाभ | खानपान उद्योग में अनसंग नायक. | औद्योगिक बर्फ मशीनों की तुलना में सीमित क्षमताएं. |

| गुणवत्ता & स्पष्टता | स्पष्टता के मेस्ट्रोस, सटीकता की पेशकश. | बादल खामियों के साथ बर्फ का उत्पादन कर सकते हैं. |

| उत्पादन & क्षमता | बड़े पैमाने पर खानपान के लिए उच्च-मात्रा का उत्पादन. | बड़े पैमाने पर उत्पादन के लिए सीमित स्केलेबिलिटी. |

| तुलना | उन्नत तकनीक लगातार स्पष्ट बर्फ सुनिश्चित करती है. | अक्सर क्रिस्टल-क्लियर पूर्णता देने से कम हो जाता है. |

| महत्व | बड़े पैमाने पर संचालन में उत्कृष्टता प्रदान करने के लिए आवश्यक है. | रोजमर्रा के उपयोग के लिए उपयुक्त है लेकिन औद्योगिक मशीनों की सटीकता का अभाव है. |

| समग्र फैसला | पूर्णता की खोज में निर्विवाद चैंपियन. | रोजमर्रा के उपयोग के लिए पर्याप्त हो सकता है, लेकिन एक अद्वितीय अनुभव देने में कम हो जाता है. |

औद्योगिक बर्फ मशीनों और उनकी विशेषताओं के प्रकार

| औद्योगिक बर्फ मशीन का प्रकार | विशेषताएँ |

| स्पष्ट बर्फ ब्लॉक मशीनें | ● स्पष्ट बर्फ पूर्णता के लिए विशेष मशीनरी. ● उन्नत ठंड तकनीकों का उपयोग करता है. ● हर क्यूब में अद्वितीय स्पष्टता सुनिश्चित करता है. |

| अंतर्निहित निस्पंदन प्रणालियों के साथ बर्फ निर्माता | ● अशुद्धियों के खिलाफ द्वारपाल के रूप में कार्य करता है. ● प्राचीन बर्फ में बदलने से पहले पानी को शुद्ध करें. ● अपेक्षाओं से परे शुद्धता के लिए सक्रिय दृष्टिकोण. |

| विभिन्न बर्फ प्रकारों के लिए संयोजन मशीनें | ● विविध उद्योग की जरूरतों के लिए बहुमुखी इंजीनियरिंग खानपान. ● स्पष्ट बर्फ के टुकड़े और आकार/प्रकार का एक स्पेक्ट्रम पैदा करता है. ● प्रौद्योगिकी में असीम संभावनाओं को प्रदर्शित करता है. |

| निरंतर उत्पादन के लिए स्वचालित बर्फ मशीन प्रणाली | ● तेज-तर्रार खानपान की दुनिया के लिए आदर्श. ● स्पष्ट बर्फ के टुकड़े का निरंतर प्रवाह सुनिश्चित करता है. ● दक्षता के लिए प्रौद्योगिकी का निर्बाध एकीकरण. ● उच्च मांग में पूर्णता की निर्बाध आपूर्ति. |

ब्लास्ट फ्रीजर और स्पष्ट बर्फ उत्पादन में उनकी भूमिका

ठंड के अनसंग हीरो:

उसे दर्ज करें ब्लास्ट फ्रीजर, ठंड में एक अनसंग नायक. स्पष्ट बर्फ उत्पादन में, ये चमत्कार एक महत्वपूर्ण भूमिका निभाते हैं, स्पष्टता और शुद्धता को पूर्णता को परिभाषित करने के लिए तेजी से ठंड.

रैपिड फ्रीजिंग सीक्रेट्स:

ब्लास्ट फ्रीजर तेजी से तकनीक के माध्यम से तेजी से ठंड हासिल करता है, बर्फ की स्पष्टता से समझौता करने के लिए अशुद्धियों और हवा के लिए समय को कम करना. यह स्विफ्ट प्रक्रिया यह सुनिश्चित करती है कि प्रत्येक घन विज्ञान और दक्षता के विवाह का एक वसीयतनामा है.

तापमान और गठन नियंत्रण:

तापमान नियंत्रण छिपा हुआ वास्तुकार है. ब्लास्ट फ्रीजर न केवल तेजी से फ्रीज करता है, बल्कि सटीक तापमान नियंत्रण भी प्रदान करता है, बर्फ को निर्दोष क्यूब्स में आकार देना. गति और नियंत्रण का संलयन इन फ्रीजर को पूर्णता के लिए अपरिहार्य उपकरणों में बदल देता है.

औद्योगिक बर्फ मशीनों के साथ सद्भाव:

स्पष्ट बर्फ उत्पादन की सिम्फनी में, औद्योगिक बर्फ मशीनें और ब्लास्ट फ्रीजर एक साथ नृत्य करें. जबकि औद्योगिक मशीनों ने मंच को ठीक से सेट किया, ब्लास्ट फ्रीजर तेजी से ठंड के साथ सौदा सील करता है. एक साथ, वे दक्षता और उत्कृष्टता का एक सामंजस्यपूर्ण मिश्रण बनाते हैं, स्पष्ट बर्फ उत्पादन के शिखर को परिभाषित करना.

स्पष्ट बर्फ उत्पादन के लिए सही औद्योगिक बर्फ मशीन का चयन करना

उत्पादन की जरूरतों का आकलन करना:

उत्पादन की जरूरतों के व्यावहारिक मूल्यांकन के साथ बर्फ की उत्कृष्टता को साफ करने के लिए यात्रा शुरू करें. डिमांड वॉल्यूम को समझना क्षमता आवश्यकताओं के साथ गठबंधन किए गए औद्योगिक बर्फ मशीन का चयन करने के लिए चरण निर्धारित करता है.

अंतरिक्ष और स्थापना को ध्यान में रखते हुए:

रूप और कार्य के नृत्य में, स्थानिक विचार केंद्र चरण लेते हैं. एक औद्योगिक बर्फ मशीन चुनें जो उपलब्ध स्थान के साथ उत्पादन की जरूरतों को संतुलित करता है, जहां स्थापना विकल्प एक आदर्श फिट सुनिश्चित करते हैं.

दक्षता और लागत का मूल्यांकन:

पूर्णता स्थिरता से समझौता नहीं करना चाहिए. औद्योगिक बर्फ मशीनों की ऊर्जा दक्षता का मूल्यांकन करें, स्पष्टता सुनिश्चित करना लागत-प्रभावशीलता और पर्यावरणीय चेतना के साथ संरेखित करता है.

विश्वसनीयता और वारंटी पर शोध करना:

मशीनरी में, विश्वसनीयता सर्वोपरि है. अनुसंधान स्पष्ट बर्फ उत्कृष्टता की खोज में विश्वसनीय ब्रांडों का खुलासा करता है. वारंटी विकल्प एक सुरक्षा जाल के रूप में कार्य करते हैं, दीर्घायु और मन की शांति सुनिश्चित करना.

औद्योगिक बर्फ मशीनों के लिए रखरखाव और सफाई युक्तियाँ

- बर्फ की गुणवत्ता के लिए नियमित सफाई: बर्फ को शुद्ध और अशुद्धियों से मुक्त सुनिश्चित करने के लिए नियमित सफाई के साथ चल रहे रखरखाव के लिए प्रतिबद्ध.

- अनुशंसित तकनीकों और उत्पादों: सफाई एक कला है. बर्फ की स्पष्टता को संरक्षित करने के लिए सटीक रूप से चुनी गई अनुशंसित तकनीकों और उत्पादों का उपयोग करें - शिल्प कौशल का उत्सव.

- दीर्घायु के लिए निवारक रखरखाव: सक्रिय रखरखाव सुनिश्चित करता है कि औद्योगिक बर्फ मशीन एक स्टालवार्ट साथी बनी हुई है, इसकी दीर्घायु और स्थायी उत्कृष्टता की रक्षा करना.

- मुद्दों और समस्या निवारण युक्तियाँ: यहां तक कि मजबूत मशीनें चुनौतियों का सामना करती हैं. संभावित मुद्दों को समझें और समस्या निवारण युक्तियों को तैयार करें - यह बर्फ पूर्णता को साफ करने के लिए यात्रा में वृद्धि के लिए एक कम्पास है.

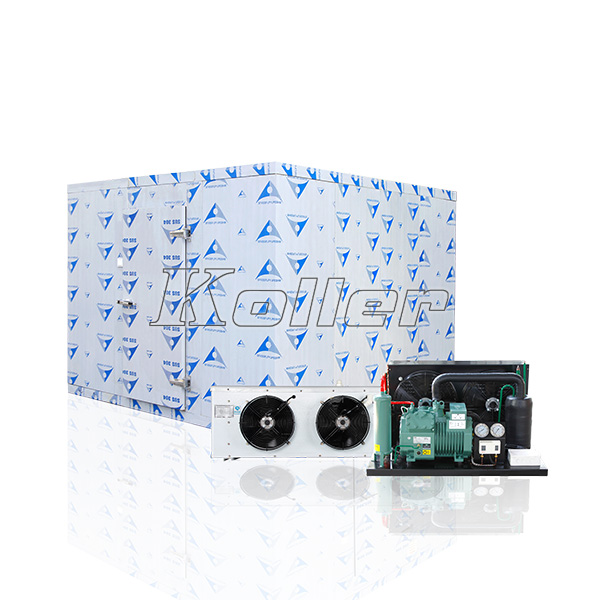

आइस स्टोरेज के लिए कोल्ड रूम सेटअप का अनुकूलन

- कोल्ड रूम के लाभ: कोल्ड रूम कैटरिंग इंडस्ट्री में अभिभावकों के रूप में खड़े हैं, स्पष्ट बर्फ के क्यूब्स को संरक्षित करना जब तक कि वे उत्तम पेय को अनुग्रहित करने के लिए तैयार न हों.

- कुशल कोल्ड रूम डिजाइन: एक ठंडा कमरा डिजाइन करना एक कला रूप है, प्रत्येक घन को यह सुनिश्चित करने के लिए अंतरिक्ष की एक सिम्फनी बनाना.

- तापमान नियंत्रण और आर्द्रता: तापमान और आर्द्रता संरक्षण में मूक कंडक्टर हैं. इन तत्वों को समझना कोल्ड रूम को एक आश्रय स्थल बनाता है, अपनी स्पष्टता और पवित्रता शिखर पर बर्फ बनाए रखना.

- बर्फ की गुणवत्ता के लिए प्रौद्योगिकी: कोल्ड रूम टेक्नोलॉजी, संरक्षण से परे एक नवाचार, सुनिश्चित करता है. यह संरक्षण का विकास है, सिर्फ स्टोरेज नहीं.

पेय प्रस्तुतियों में क्रिस्टल स्पष्ट बर्फ दिखाना

- कॉकटेल विजुअल को बढ़ाना: स्पष्ट बर्फ क्यूब्स को स्पॉटलाइट करके दृश्य कृतियों में कॉकटेल को ऊंचा करें. प्रत्येक घन एक गहना बन जाता है, इंद्रियों को लुभाने और पेय को एक कलात्मक प्रस्तुति में बदलना.

- रचनात्मकता के लिए विविध आकार: स्पष्ट बर्फ एक बहुमुखी कैनवास प्रदान करता है. मिक्सोलॉजिस्ट की रचनात्मकता को उजागर करने के लिए विविध आकृतियों और आकारों का अन्वेषण करें, कला और मिश्रण के एक संलयन में साधारण प्रस्तुति को पार करना.

- गार्निश के साथ पूरक: फ्लेवर और सौंदर्यशास्त्र का तालमेल केंद्र चरण लेता है. गार्निश और फलों के साथ स्पष्ट बर्फ के टुकड़े को पूरक करें, प्रत्येक पेय को एक संवेदी सिम्फनी में बदलना - तालू पर और स्मृति में एक क्यूरेटेड अनुभव.

- दृश्य प्रभाव के लिए प्रयोग करना: प्रयोग के माध्यम से ग्रैंड फिनाले को प्रकट करें. प्रकाश और सेवारत तकनीकों के साथ खेलें, एक संवेदी तमाशा बनाना जो संरक्षक पर एक अमिट निशान को लुभाता है और छोड़ देता है’ यादें.

खानपान में स्पष्ट बर्फ उत्पादन का भविष्य

- स्पष्ट बर्फ प्रौद्योगिकी में प्रगति: पूर्णता की यात्रा प्रौद्योगिकी के साथ विकसित होती है, यहां तक कि स्पष्ट बर्फ के क्यूब्स का वादा. इसकी प्रगति उत्कृष्टता को फिर से परिभाषित करने के लिए स्पष्टता सीमाओं को आगे बढ़ाने के अथक खोज से ईंधन की जाती है.

- आतिथ्य में बढ़ती मांग: स्पष्ट बर्फ की उत्कृष्टता कुलीन स्थानों को स्थानांतरित करती है, सभी कैलिबर के रेस्तरां और बार के माध्यम से गूंज. बढ़ती मांग एक सांस्कृतिक बदलाव का संकेत देती है जहां संरक्षक हर घूंट में असाधारण को तरसते हैं.

- अभिनव व्यंजनों में स्पष्ट बर्फ: स्पष्टता और रचनात्मकता का विवाह नई ऊंचाइयों तक पहुंचता है. अभिनव पेय व्यंजनों में स्पष्ट बर्फ को शामिल करना मिक्सोलॉजिस्ट के लिए स्वाद और सौंदर्यशास्त्र की कहानियों को बुनने के लिए एक कैनवास बन जाता है.

- क्रिस्टल स्पष्ट बर्फ के लिए रुझान और भविष्यवाणियां: उद्योग के रुझान और भविष्यवाणियां एक भविष्य की कल्पना करती हैं जहां क्रिस्टल स्पष्ट बर्फ एक कालातीत मानक बन जाता है, सिर्फ एक प्रवृत्ति नहीं. यह पूर्णता के स्थायी आकर्षण के लिए एक वसीयतनामा है खानपान दुनिया.

निष्कर्ष

क्रिस्टल क्लियर आइस में ड्रिंक अनुभव को बढ़ाने की असाधारण क्षमता है, औद्योगिक बर्फ मशीनों और ब्लास्ट फ्रीजर के क्रांतिकारी प्रभाव द्वारा बढ़ाई गई एक शक्ति. एक साथ, वे स्पष्ट बर्फ उत्पादन में उत्कृष्टता के मानकों को फिर से परिभाषित करते हैं, एक भविष्य का वादा करना जहां स्पष्टता केवल एक प्रवृत्ति नहीं है, बल्कि खानपान उद्योग में पूर्णता की एक कालातीत पहचान है.