Ice is essential in many industries, such as food processing, beverage production, chemical manufacturing, and healthcare. Choosing a commercial ice-making machine for your business can significantly improve productivity, quality, and profitability.

However, with so many available options, how do you know which industrial ice maker is best for your needs? This article will discuss the top six things to consider when choosing an industrial ice machine.

Determine Your Ice Needs

When searching for a commercial ice making machine, it’s essential to identify the type of ice your business requires. Commercial ice making machines come in various forms, each producing different kinds of ice with unique shapes, sizes, and characteristics.

By understanding your industry and application requirements, you can choose the right commercial ice making machine that meets your needs. Some of the most common types of ice are:

Cube Ice

Cube ice making machines are the most popular choice for beverages and food service. It has a precise and rugged appearance and can last longer than other types of ice. Cube ice can be made in different sizes, such as full cubes, half cubes, or gourmet cubes.

Ball Ice

Ball ice making machines produce spherical ice, ideal for cocktails and premium drinks. It has a smooth and elegant appearance and can chill drinks faster than cube ice.

Flake Ice

Flake ice making machines create soft and flaky ice, ideal for food displays, such as seafood, meat, and vegetables. It can also be used for cooling and mixing applications, such as concrete cooling and bakery dough cooling.

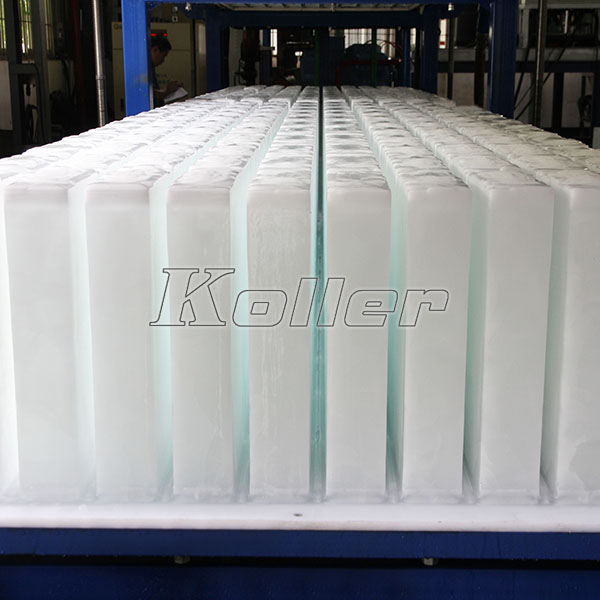

Plate Ice

Plate ice making machines produce flat and thin ice, ideal for industrial cooling and freezing applications, such as fish processing, chemical manufacturing, and concrete curing. Plate ice can be made in different thicknesses, depending on the application.

Tube Ice

Tube ice making machines create cylindrical ice with a hollow center, ideal for beverage cooling and ice vending machines. Depending on the application, tube ice can be made in different diameters and lengths.

Choose the type of ice that suits your industrial ice machine application, depending on your industry and application. You should also consider the quality of the ice, such as its clarity, hardness, purity, and taste.

Consider Production Capacity

The second thing to consider is how much ice you need for your business. The production capacity of an industrial ice-making machine refers to how much ice it can produce in 24 hours. The production capacity depends on various factors, such as the ambient temperature, water temperature, water pressure, and power supply.

It would help if you chose an industrial icemaker to meet your peak demand without compromising quality or efficiency. You should also consider the storage capacity of the machine, which refers to how much ice it can store at a time. The storage capacity should match the production capacity to avoid wasting or running out of ice.

Different types of industrial ice-making machines are available in the market with varying production capacities. Some of the most common types are:

Modular Ice Machines

These are machines that consist of two separate units: an ice maker and an ice bin. The ice maker produces ice and drops it into the container for storage. Modular ice machines are ideal for large-scale applications that require high volumes of ice. They can have up to 1 ton of ice per day or more.

Self-contained Ice Machines

These machines have an integrated unit with an ice maker and an ice bin. The ice maker produces ice and stores it in a container for easy access. Self-contained ice machines are ideal for small-scale applications requiring moderate ice volumes. They can pay up to 500 kg of ice per day or less.

Undercounter Ice Machines

These machines have a compact design that fits under a counter or a table. They have a built-in bin that stores the produced ice. Undercounter ice machines are ideal for space-limited applications requiring low ice volumes. They can make up to 150 kg of ice per day or less.

Determine Your Water Supply

The third thing to consider is the quality and quantity of your water supply. The water supply affects the performance and longevity of your industrial ice-making machine. Poor water quality can cause problems such as scale buildup, corrosion, bacteria growth, and bad-tasting ice.

Choose an industrial ice machine with a compatible water inlet and outlet connection with your water source. Installing a water filtration system is also essential to remove impurities and contaminants from your water supply. There are different types of water filtration systems available for commercial ice-making machines, including:

Particulate Filters

These can remove solid particles, such as sand, dirt, rust, and sediment, from the water. Particulate filters can protect the machine from clogging and abrasion and improve the clarity of the ice.

Carbon Filters

These can remove organic compounds, such as chlorine, chloramine, pesticides, and herbicides, from the water. Carbon filters can protect the machine from corrosion and improve the taste and odor of the ice.

Reverse Osmosis Systems

These can remove dissolved minerals, such as calcium, magnesium, iron, and sodium, from the water. Reverse osmosis systems can protect the machine from scale buildup and improve the hardness and purity of the ice.

Select the appropriate water filtration system for your commercial ice-making machine based on your water quality and ice type. Regular monitoring and maintenance of the water filtration system are crucial to ensure optimal performance and efficiency.

Evaluate Energy Efficiency

As you search for an ice making machine for sale, be sure to examine the energy efficiency of each model. The energy efficiency of an ice machine refers to the amount of electricity consumed to produce a certain quantity of ice. Energy efficiency not only impacts your operating costs but also affects your environmental footprint. Select an ice making machine for sale with a high energy efficiency rating in line with local standards and regulations.

It would help if you also looked for energy-efficient features that can reduce power consumption and improve the machine’s performance. Some of the energy-efficient features available in commercial ice-making machines are:

High-efficiency Compressors

These compressors use less electricity to compress the refrigerant gas and create the cooling effect. High-efficiency compressors can save up to 20% of energy compared to standard compressors.

Low-energy Ice Making Cycles

These processes use less water and electricity to produce ice. Low-energy ice making cycles can save up to 10% of energy compared to standard ice making cycles.

Smart Controls

These are controls that monitor and adjust the operation of the machine according to the ambient conditions and demand. Intelligent controls can optimize ice production and storage, reduce maintenance needs, and prevent wastage or shortage of ice.

Maintenance and Cleaning

The fifth thing to consider is maintaining and cleaning your industrial ice-making machine. Maintenance and cleaning are essential to ensure your device’s optimal performance and hygiene. Poor care and cleaning can cause problems such as reduced ice quality, lower ice production, higher energy consumption, and shorter lifespan.

Before committing to a purchase, research the ice making machine manufacturer to ensure they have a solid reputation in the industry. A reputable manufacturer should offer a warranty and reliable after-sales support. You can expect improved performance, durability, and lower maintenance costs over time by choosing a high-quality machine from a trustworthy ice-making machine manufacturer.

It would help if you chose an industrial ice machine with a simple and user-friendly design that allows easy access and cleaning. You should also follow the manufacturer’s instructions and recommendations for regular maintenance and cleaning.

Some of the maintenance and cleaning tasks that you should perform for your industrial ice-making machine are:

Daily

Wipe down the machine’s exterior with a damp cloth and sanitize the ice scoop and bin with a food-grade sanitizer.

Weekly

Check and replace the water filter if necessary. You should also check the condenser coil and fan for dust or debris and clean them with a soft brush or vacuum cleaner.

Monthly

Thoroughly clean the machine with a specialized cleaner that can remove any scale, slime, or mold from the interior surfaces. You should also inspect the device for wear or damage and repair or replace faulty parts.

Choose an industrial ice machine from a reputable manufacturer with a warranty and after-sales support. It would be best to find a local service provider specializing in commercial ice machine repair and maintenance. Regular maintenance and timely repairs can significantly extend the lifespan of your industrial ice machine and reduce its total cost of ownership.

Consider Your Budget

The sixth thing to consider is the cost of the industrial ice machine and the available financing options. The price of an industrial ice-making machine depends on factors such as the type, size, capacity, features, and brand. Generally, commercial ice machines can range from a few thousand dollars for small under-counter units to tens of thousands for large modular systems.

When budgeting for your industrial ice machine, consider ongoing costs, such as electricity, water, consumables, maintenance, and repairs. It would help if you calculated the total cost of ownership to determine the return on investment and the affordability of the device.

Choose an industrial ice machine with a reasonable price that fits your business budget. Consider factors influencing the machine’s cost, such as:

- Production capacity: Higher production capacities result in higher prices.

- Storage capacity: Larger storage capacities lead to higher prices.

- Energy efficiency: Greater energy efficiency corresponds to higher prices.

Different financing options for purchasing a commercial ice machine include leasing, loans, and payment plans.

Leasing provides the option to rent the machine for a fixed period at a set monthly rate, without requiring upfront costs. On the other hand, loans enable you to borrow the money needed to purchase the device, which can then be repaid over time, along with interest. Alternatively, payment plans offer the convenience of paying for the machine in installments, with or without accruing interest.

Choose the financing option that suits your budget and cash flow. Consult with a financial advisor to determine your business’s most suitable financing option.

Conclusion

Selecting the perfect industrial ice machine for your business can be daunting, as it requires a careful evaluation of various factors that influence your needs, preferences, and budget.

We hope this comprehensive guide has provided valuable insights and equipped you with the knowledge required to make an informed choice when selecting an industrial ice machine. Remember that each business is unique, and finding the suitable ice machine tailored to your specific needs will ultimately contribute to the efficiency and productivity of your operations.

If you have any questions or require further assistance in making a decision, please do not hesitate to contact us. Our experienced professionals are always ready to help and provide you with the support and guidance necessary to ensure you make the best choice for your business.