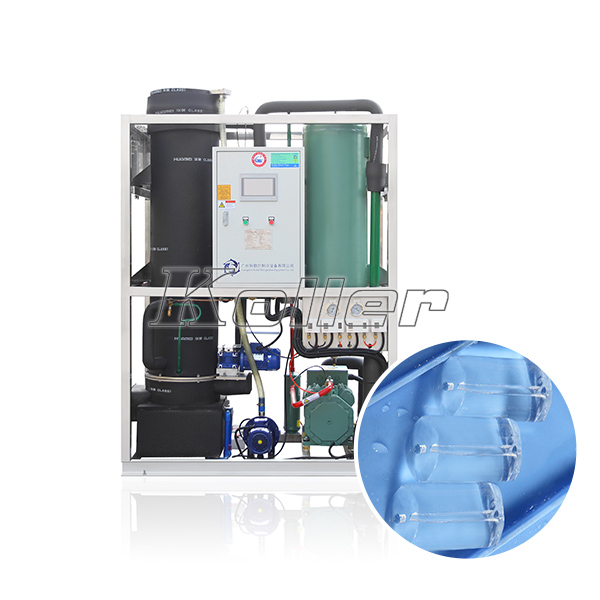

Tube Ice Machine

The inner and outer diameters of the tube ice can be customizable. The tube ice with a clear and aesthetically pleasing performance from Koller’s ice machine won’t melt easily. All sizes are even for every tube with less crushed Ice.

Koller's Innovation Delivers More

Clean & edible ice through food grade 304 stainless steel

No leakage or stuck ice with seamless steel pipe

Persistant capacity in a long time with premium quality

Power & water consumption less than other machine types

Featured Machine Models

A broad assortment of options with different capacities up to 30 tons.

Daily Capacity

30 ton/day

Dimension (mm)

Refrigeration: 3500*2300*2400; Evaporator: 1700*1700*6150

Prefer A Cost-friendly Choice?

Tube ice machine evaporator as the main part is available for assembling on your own.

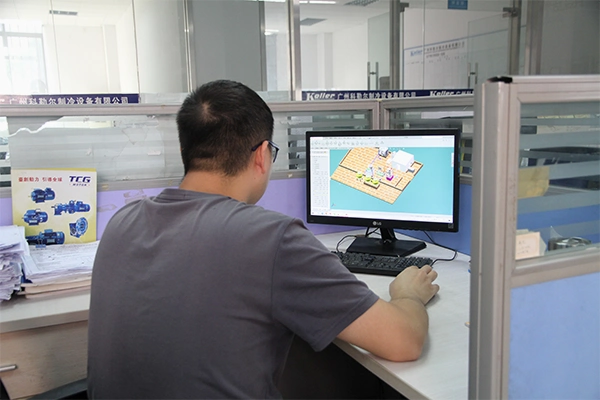

Bespoke Solution for Your Application

Get exhausted by too much parameters and machine details? Leave us a message about your application and our consultants will head back to you with a detailed solution.

- Application, capacities, and voltage.

- Automatic system, like water filling, de-icing, remote monitoring.

- Convenient matching device, like ice crusher, package machine.

The Key to Your Cooling Success

Over decades, Koller has focused on machine innovation for less energy, high efficiency, and durable quality in one stop.

Branded Components

With reliable material supply chains from well-known brands around the world, quality is committed. And it is more convenient for you to find spare parts in your domestic countries.

Branded Components

With reliable material supply chains from well-known brands around the world, quality is committed. And it is more convenient for you to find spare parts in your domestic countries.

High Automation

Touchscreen PLC design is easy to make and demold ice easily and automatically. 5 Default languages for your domestic location, including English, Spainish, French Arabic and Chinese.

High Automation

Touchscreen PLC design is easy to make and demold ice easily and automatically. 5 Default languages for your domestic location, including English, Spainish, French Arabic and Chinese.

Safety Protection System

Protect the machines and operators and maintain the durability at all levels, such as overload, low pressure, water shortage and so on.

Safety Protection System

Protect the machines and operators and maintain the durability at all levels, such as overload, low pressure, water shortage and so on.

Eco & Cost-friendly

Equipped with water circulation system, it is available to save water and shorten the process time, bringing more profitable and social value to your business.

Eco & Cost-friendly

Equipped with water circulation system, it is available to save water and shorten the process time, bringing more profitable and social value to your business.

Air-Cooled Vs. Water Cooled Ice Machines

Two effective way to exhausts the heat from ice making in regular ice machines.

Air Cooling

With the help of internal fans, air can move heat through the condenser coils and release it out at vents. Suitable for commercial machine works in clean, temperature-controlled environments.

- Cost-friendly without the cost of running water

- Less energy need, better for the environment

- Easy installment, maintainance and repairment

Water Cooling

Water runs through the inner pipe to cool down the heat. Available for industrial machine working in various places and applications, such as edible ice, directly contact with food.

- Speedy cooling and freezing the heat in a short time

- Clean ice without contamination with grease and dust

- Koller's water circulated system reduces water cost

Tube Ice Applications

Fisheries & Seafood Transportation

Tube ice plays a crucial role in the fishing industry. It is used for preserving and icing freshly caught fish, ensuring they remain fresh during transportation and storage.

Food Processing & Preservation

Tube ice finds applications in food processing operations, seafood processing, poultry processing, and bakeries. It helps rapidly chill and cool perishable food items, ensuring their freshness and maintaining quality.

Beverage Industry & Bars

Tube ice is widely used in bars, restaurants, hotels, and the beverage industry to chill and preserve a variety of drinks, including soft drinks, cocktails, juices, and alcoholic beverages.

Supermarkets & Grocery Stores

Tube ice is utilized in supermarket displays and grocery stores to keep perishable foods, such as seafood, meat, fruits, and vegetables. It assists in maintaining the necessary low temperatures and preventing spoilage.

Concrete Cooling for Construction

Tube ice is used in construction projects for concrete cooling. When mixed with water, it helps bring down the temperature of the concrete during the mixing and pouring processs.

How to Make Tube Ice ?

1. Set Up the Machine

Install and properly connect the ice tube machine according to the industrial ice maker manufacturer’s instructions.

2. Water Filtration

Connect a reliable water source to the ice machine. It is important to have a water filtration system in place to remove impurities and ensure the production of clean, high-quality tube ice.

3. Start the Machine

Power on the industrial ice machine and set it to the tube ice production mode. The specific steps may vary depending on the machine’s design and controls. Refer to the manufacturer’s instructions for details on operating your particular machine.

4. Freezing Process

The ice machine will initiate the freezing process. Water will be pumped into the ice molds or tubes within the machine.

5. Harvesting

Once the ice has formed and solidified inside the molds or tubes, the machine will initiate the harvesting process. The ice tubes are then typically dropped into a collection bin.

6. Cutting and Storage

After harvesting, the ice tubes may be cut into desired lengths using a cutting mechanism integrated into the machine. The cut tube ice is collected in an ice storage bin or bin liner to keep it frozen until it is ready for use.

Tube Ice vs Cube Ice

| Category | Tube Ice | Cube Ice |

|---|---|---|

| Shape | Cylindrical or tube-shaped | Cuboidal or square |

| Size | Length varies, typically shorter | Uniform size, various dimensions |

| Cooling | Slower cooling due to thickness | Faster cooling due to surface area |

| Melting | Melts slower due to thickness | Melts faster due to larger surface |

| Aesthetics | May clump together (depending on storage) | More visually appealing |

| Dilution | Melts less and dilutes beverages less | Melts faster and may dilute beverages faster |

| Application | Beverage industry, food preservation, fishing, concrete cooling | Beverage industry, food service, cooling drinks, parties |