Industrial ice machines are an essential part of many food and beverage operations, providing a constant supply of ice for everything from fountain drinks to seafood storage. However, these machines can also pose a risk to food safety if not properly maintained and managed.

In this article, we’ll discuss the best practices for ensuring food safety with industrial ice machines, including common contaminants found in ice, best practices for maintenance, water quality considerations, and choosing the right industrial ice maker. By following these recommendations, you can help ensure the safety and quality of the ice you produce and the food it is used in.

Common Contaminants Found in Ice

Ice can become contaminated with a variety of harmful substances that pose a risk to food safety. Some of the most common contaminants found in ice include bacteria, mold, and viruses.

Bacteria

Bacteria can easily grow and multiply on ice, especially when it is stored at temperatures above freezing. This can lead to the development of harmful species such as E. coli, Salmonella, and Listeria. These bacteria can cause serious illness and even death in certain individuals, particularly those with weakened immune systems.

Mold

Mold is another common contaminant that can develop on ice, particularly when it is stored in damp or humid conditions. This can lead to the growth of toxic species such as Aspergillus and Penicillium, which can cause allergies and respiratory problems in certain individuals.

Viruses

Viruses can also be present in ice, particularly those that are transmitted through water sources such as norovirus and hepatitis A. These viruses can cause serious illness and can spread easily through contaminated ice.

It’s important to note that these contaminants can pose a risk to food safety and can lead to the spread of food-borne illnesses. It’s critical to take steps to prevent the growth and development of these harmful substances in ice to ensure the safety and quality of the food and beverages that it comes in contact with.

Best Practices for Maintaining Industrial Ice Machines

Regular maintenance is crucial in ensuring the smooth and efficient operation of industrial ice machines. Neglecting maintenance can lead to bacterial and mold growth, resulting in contamination of the ice and potential health risks for consumers.

Common Maintenance Tasks

Common maintenance tasks for industrial ice machines include regular cleaning, daily inspections, and scheduled maintenance performed by trained technicians. Regular cleaning and inspection of the machine helps detect any developing issues and prevent bacteria and mold growth between service appointments.

Tips for Preventing Mold Growth

To prevent mold growth, it’s important to keep the machine and surrounding area clean and dry. Daily cleaning of the ice machine with an approved sanitizer can help prevent the buildup of mold, while keeping the area surrounding the machine dry can prevent the growth and spread of mold spores.

Tips for Controlling Bacteria

Controlling bacteria growth requires the regular cleaning and disinfection of ice machine surfaces. It’s essential to follow the industrial ice machine manufacturers‘ cleaning guidelines and to use approved cleaning solutions to ensure effective disinfection. Using ultraviolet (UV) or ozone disinfection can also be effective in killing bacteria and preventing growth.

Finally, it’s important to perform regular maintenance tasks such as checking and replacing worn parts and identifying and repairing leaks. This is critical to preventing bacterial contamination and ensuring the longevity of your industrial ice machine.

Overall, regular maintenance is critical to ensuring the safety and quality of the ice produced by industrial ice machines. By following best practices for maintenance, you can prevent mold growth, control bacteria, and ensure the efficient and effective function of your machine, resulting in high-quality and safe ice for your customers.

Water Quality Considerations

The quality of the water used in ice making is a critical factor in ensuring the safety and quality of the ice produced. Using high-quality water is essential to prevent the growth and spread of harmful contaminants in the ice.

Taste & Safety of the Ice

One important consideration is the type of water used in ice making. Distilled or purified water is typically the best choice for industrial ice machines, as it lacks the impurities and contaminants found in tap water that can affect the taste and safety of the ice.

Texture & Appearance of the Ice

Water quality can also affect the texture and appearance of the ice. High mineral content in water can result in cloudy or discolored ice, while water that is too soft can produce brittle and cloudy ice.

Efficiency & Lifespan of Industrial Ice Machines

Additionally, water quality can impact the efficiency and lifespan of industrial ice machines. Hard water with high levels of mineral content can cause mineral buildup in the machine, reducing its efficiency and potentially causing mechanical issues.

Overall, using high-quality water is essential for producing safe, high-quality ice. By choosing the right type of water and ensuring its quality, you can help ensure that the ice produced by industrial ice machines is safe and high-quality.

Choosing the Right Industrial Ice Maker

| Type | Ice Type | Application | Features |

| Tube Ice Machine | Cylindrical, slow-melting | Ideal for cocktails, smoothies, seafood and produce. | Compact, efficient, with a low melting rate |

| Flake Ice Machine | Small, thin flakes | Ideal for display of food products, blended beverages | Soft texture, high cooling capacity, energy-efficient |

| Plate Ice Machine | Solid, plate-like ice | Ideal for high-volume storage and transport of food products | Large blocks of ice with long melting time, suitable for industrial cooling needs |

| Ice Cube Machine | Hard, clear ice cubes | Ideal for use in drinks and cocktails | Various sizes available, depending on intended application |

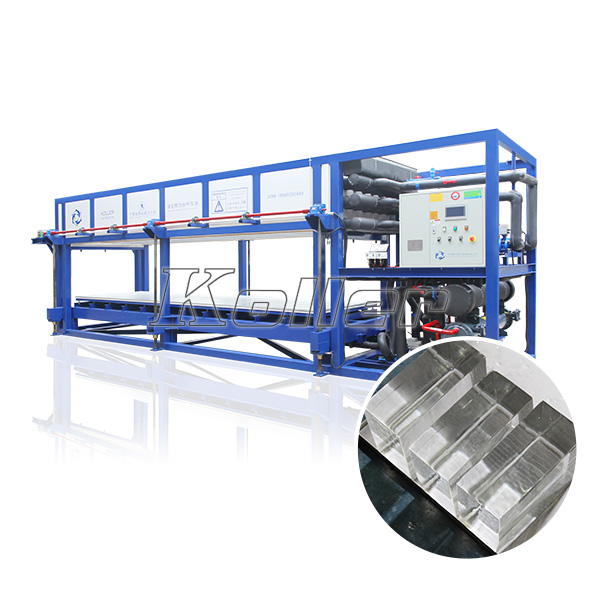

| Ice Block Machine | Large blocks of ice, often used in ice shavers or molded into other shapes | Ideal for industrial and construction cooling | Efficient production and storage capacity |

| Ball Ice Machine | Perfectly round balls of ice, preferred for colder drinks | Ideal for colder drinks | Slow melting rate, used in high-end bars and restaurants |

There are several types of industrial ice makers to choose from, each with their specific strengths and advantages. Understanding the different types can help you choose the best machine for your specific food industry application.

- Tube ice machines: These machines produce cylindrical ice that is slow-melting and ideal for use in beverages such as cocktails and smoothies. They are also suitable for cooling and storing seafood and produce due to their long melting time.

- Flake ice machines: These machines produce small, thin flakes of soft ice that are ideal for displaying food products such as salad bars and seafood displays. Flake ice is also ideal for use in blended food and beverage products.

- Plate ice machines: These machines produce solid, plate-like ice that is preferred for high-volume storage and transport of food products. Plate ice is large, slow-melting, and suitable for industrial cooling needs such as in meat and poultry processing.

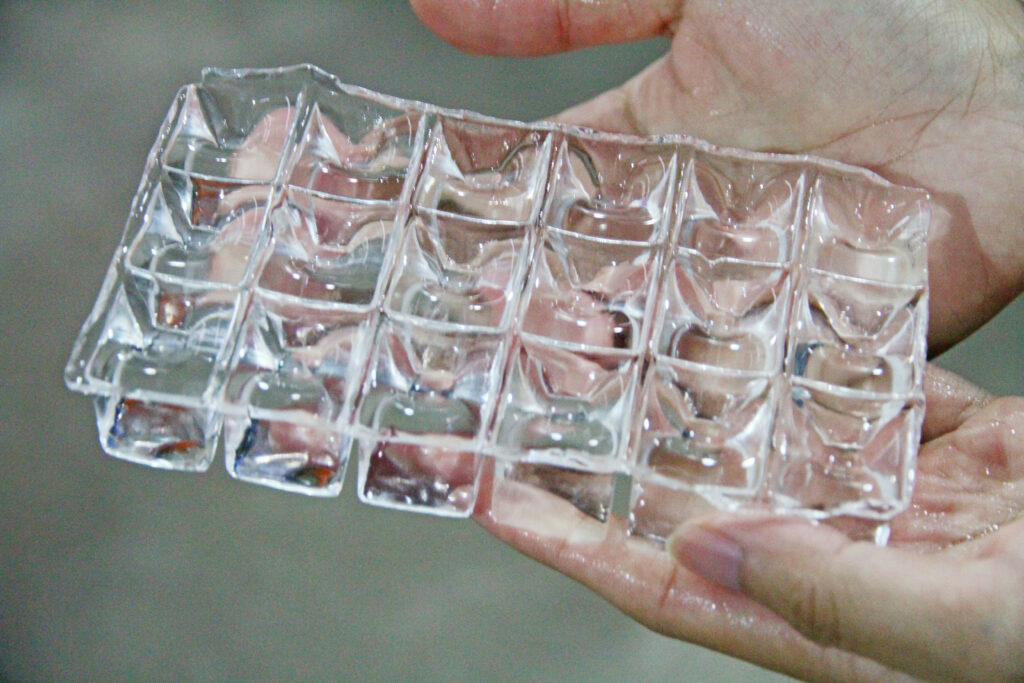

- Ice cube machines: These machines produce hard, clear ice cubes that are ideal for use in drinks and cocktails. They come in various sizes, depending on the intended application.

- Ice block machines: These machines produce large blocks of ice that are often used in shavers or molded into other shapes. Ice blocks are also used for industrial and construction cooling needs.

- Ball ice machines: These machines produce perfectly round balls of ice that are popular in high-end bars and restaurants. Ball ice has a slower melting rate and is preferred for colder drinks.

When choosing an industrial ice maker, it’s essential to consider your specific needs and the application of the ice produced. Factors to consider include production volume, required ice type, size, and shape, maintenance and energy requirements as well as a reliable industrial ice machine manufacturers.

By carefully selecting the right type of industrial ice maker, you can ensure that your ice production meets your specific needs, resulting in safe and high-quality ice for your customers.

Conclusion

Industrial ice machines are critical to many food and beverage operations, but they can also pose a risk to food safety if not properly maintained and managed.

To ensure the safety and quality of the ice produced, it’s essential to use high-quality water, follow proper maintenance procedures, and choose the right type of industrial ice maker for your specific needs. By taking these steps, you can prevent the growth and spread of harmful contaminants in the ice and ensure the safety and quality of the food and beverages it is used in.

We encourage readers to follow the best practices discussed in this article to help ensure the safety and quality of their ice and the food it is used in. By doing so, you can help prevent foodborne illnesses and ensure that your customers are served safe and high-quality food and beverages.