Welcome to our comprehensive guide on walk-in coolers and freezers. This article will provide all the essential information about these indispensable refrigeration solutions, from understanding their components and benefits to troubleshooting common problems and maintaining their efficiency.

Whether you are a business owner seeking to improve your operations or a curious individual interested in learning more about walk-in coolers and freezers, this guide will be a valuable resource. Dive in and explore the world of walk-in coolers and freezers, and discover how they can contribute to the success of your business.

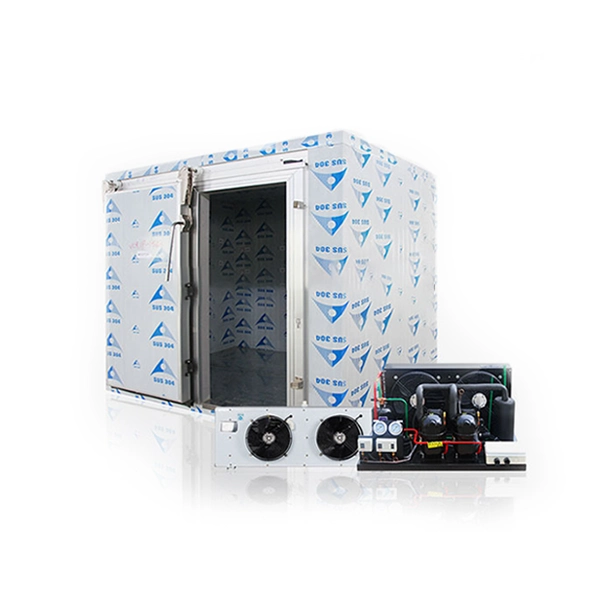

What is a Walk-In Cooler or Freezer?

A walk-in cooler or freezer is a large refrigerated room that can store and preserve food, beverages, and other perishable items at low temperatures. Unlike standard refrigerators or freezers, walk-in coolers or freezers can accommodate larger quantities and sizes of products and allow easy access and organization. These cooling rooms are essential for businesses that require large-scale storage solutions.

In addition to their use in various industries, industrial ice machine applications are commonly integrated into walk-in coolers and freezers for on-site ice production, making them essential for businesses such as restaurants, supermarkets, laboratories, and food processing plants.

Benefits of Walk-In Cooler or Freezer

The following are some benifits of walk-in cooler or freezer:

- Extending the shelf life and quality of food products by preventing spoilage and bacterial growth.

- Reducing food waste and saving money by minimizing product loss and inventory shrinkage.

- Increasing operational efficiency and customer satisfaction by ensuring product availability and freshness.

- Complying with food safety regulations and standards by maintaining proper temperature and hygiene.

Walk-In Cooler/Freezer Components

A walk-in cooler or a walk-in freezer,also known as a cold room, consists of several components that work together to create a controlled environment for refrigeration. These components include:

Door

The door is the walk-in cooler or freezer’s main entrance and exit point. It should be well-insulated, durable, and easy to open and close. It should also have a proper seal to prevent air leakage and heat transfer. Some doors may have features such as windows, locks, alarms, or automatic closers for added security and convenience.

Walls

The walls are the structural elements that enclose the walk-in cooler or freezer. They should be made of sturdy materials that withstand external weather conditions and internal temperature fluctuations. They should also be insulated with foam or fiberglass to reduce heat loss and condensation.

Flooring

The flooring is the surface that supports the weight of the products and equipment inside the walk-in cooler or freezer. It should be firm, slip-resistant, and easy to clean. It should also be insulated to prevent heat transfer from the ground. Some walk-in coolers or freezers may have no flooring and require a concrete slab or foundation.

Insulation

Insulation is the material that fills the space between the walls, flooring, and ceiling of the walk-in cooler or freezer. It is a barrier that prevents heat from entering or escaping the refrigerated room. It also helps to maintain a consistent temperature and humidity level inside the cold room. The most common types of insulation are polyurethane foam and extruded polystyrene foam.

Refrigeration System

The refrigeration system is the mechanism that cools down and circulates the air inside the walk-in cooler or freezer. It consists of four main components: a compressor, a condenser, an evaporator, and a refrigerant.

The compressor compresses the refrigerant gas into a high-pressure liquid. The condenser cools down the liquid refrigerant and releases heat to the outside air. The evaporator absorbs heat from the inside air and evaporates the liquid refrigerant into a low-pressure gas. The refrigerant then returns to the compressor to repeat the cycle.

In addition to the main components, some walk-in coolers and freezers may also utilize industrial or commercial ice-making machines to produce ice on-site for various applications.

How to Avoid Ice Building Up

Ice buildup is a common problem that can affect the performance and efficiency of your walk-in cooler or freezer. Ice can form on the walls, ceiling, door, evaporator coil, or fan blades of your walk-in cooler or freezer due to various reasons.

Reasons

- Improper Airflow

If there is not enough ventilation or circulation of air inside your walk-in cooler or freezer, moisture can accumulate and freeze on cold surfaces. This can also happen if there are obstructions or gaps in the airflow, such as overcrowded shelves, poorly placed products, or damaged door seals.

- Malfunctioning Defrost System

If your walk-in cooler or freezer has a defrost system that periodically melts ice from the evaporator coil, it may need to be fixed due to faulty timers, sensors, heaters, or valves. This can cause ice to build up on the ring and reduce its cooling capacity.

- Insufficient Insulation

If your walk-in cooler or freezer has poor insulation or insulation damage, heat can leak into the refrigerated space and cause condensation and freezing on cold surfaces.

Measures

To avoid ice buildup in your walk-in cooler or freezer, you should:

- Regularly Check

Regularly inspect your walk-in cooler or freezer for signs of ice buildup and take appropriate actions to remove it. You should keep the door closed as much as possible and avoid placing hot or moist items inside the walk-in cooler or freezer. Consult with ice-making machine manufacturers for best practices on preventing and managing ice buildup in their products.

- Seek Professional Help

If you notice severe or recurring ice buildup in your ice making machine for sale, contact a qualified refrigeration technician or an walk-in cooler manufacturer to inspect and repair your unit. They can identify and fix any underlying issues causing the ice buildup, such as faulty components, improper installation, or inadequate ventilation.

Cleaning & Maintenance

Keeping your cooling room clean and well-maintained is essential for optimal performance and longevity. It can also help you prevent ice buildup, food contamination, and energy waste. Here are some tips for cleaning and maintaining your walk-in cooler or freezer:

Benefits

Cleaning and maintaining your walk-in cooler or freezer regularly can help you:

- Enhance the appearance and hygiene of your unit and the products inside it.

- Extend the lifespan and efficiency of your unit and its components.

- Reduce the risk of breakdowns, repairs, and replacements.

- Save money on energy bills and operating costs.

- Comply with health and safety codes and regulations.

Daily & Deep Cleaning

A daily cleaning routine for walk-in coolers or freezers is essential to eliminate spills, stains, crumbs, or debris that may gather on the floor, walls, shelves, or doors. A broom, mop, cloth, or vacuum cleaner will efficiently tackle these issues.

Additionally, wiping down the door gasket and handle with a damp cloth helps to avoid dirt and mold accumulation. Also perform a deep cleaning of your walk-in cooler or freezer at least once a month or more often, depending on the usage and condition of your unit.

A gentle detergent, warm water, and a soft brush or sponge will effectively clean your unit’s surfaces. It’s important to steer clear of abrasive cleaners, bleach, ammonia, or other harsh chemicals that could harm the finish or insulation. After cleaning, ensure surfaces are thoroughly rinsed and dried.

Regular Maintenance

Besides cleaning your walk-in cooler or freezer, you should also perform regular maintenance checks to ensure everything works correctly. Some of the tasks you should do include:

- Checking the door seal for any cracks, tears, or gaps that may allow air leakage. Monitoring the temperature and humidity level inside your unit and adjusting them as needed.

- Checking for any signs of ice buildup, condensation, or water leakage and resolving them promptly.

- Checking for equipment malfunctions, such as strange noises, vibrations, or odors, and reporting them to a technician.

- Replacing worn-out or damaged parts, such as gaskets, hinges, fans, or filters.

Troubleshooting Common Problems

Even with proper cleaning and maintenance, your walk-in cooler or freezer may still need some common problems affecting its performance and efficiency. Some of these problems include:

Temperature Inconsistency

If your walk-in cooler or freezer is not maintaining a consistent temperature level, it may be due to:

- A faulty thermostat that is not reading or regulating the temperature correctly.

- A dirty evaporator coil that is not absorbing heat effectively.

- A clogged condenser coil that is not releasing heat efficiently.

- A low refrigerant level that is not cooling the air sufficiently.

To troubleshoot these problems, you should:

- Check the thermostat settings and calibration and adjust them if needed.

- Clean the evaporator coil and defrost it if necessary.

- Clean the condenser coil and remove any debris or obstructions around it.

- Check the refrigerant level and pressure and refill it if needed.

Equipment Malfunction

If your walk-in cooler is not working at all or making unusual sounds or smells, it may be due to:

- A blown fuse or tripped circuit breaker cutting off the power supply.

- A loose or broken electrical connection is causing a short circuit or fire hazard.

- A worn-out or damaged compressor that is not compressing the refrigerant properly.

- A faulty fan motor that is not spinning the fan blades smoothly.

To troubleshoot these problems, you should:

- Check the fuse box or circuit breaker panel and replace or reset them.

- Check the electrical wiring and connections and tighten or repair them if needed.

- Check the compressor for any signs of overheating, leaking, or noise and replace it if needed.

- Check the fan motor for any signs of wear, tear, or noise and replace it if needed.

Conclusion

Walk-in coolers and walk-in freezers are crucial for businesses that require large-scale storage solutions for perishable items. Proper care, maintenance, and troubleshooting are essential for optimal performance and efficiency. Following this article’s guidelines and tips, you can ensure your walk-in cooler or freezer operates smoothly for years.

When purchasing a walk-in cooler for sale or a walk-in cooler for sale, choose a reliable ice-making machine manufacturer to guarantee a high-quality and efficient product. Consult a professional refrigeration service provider for expert advice and support if needed.