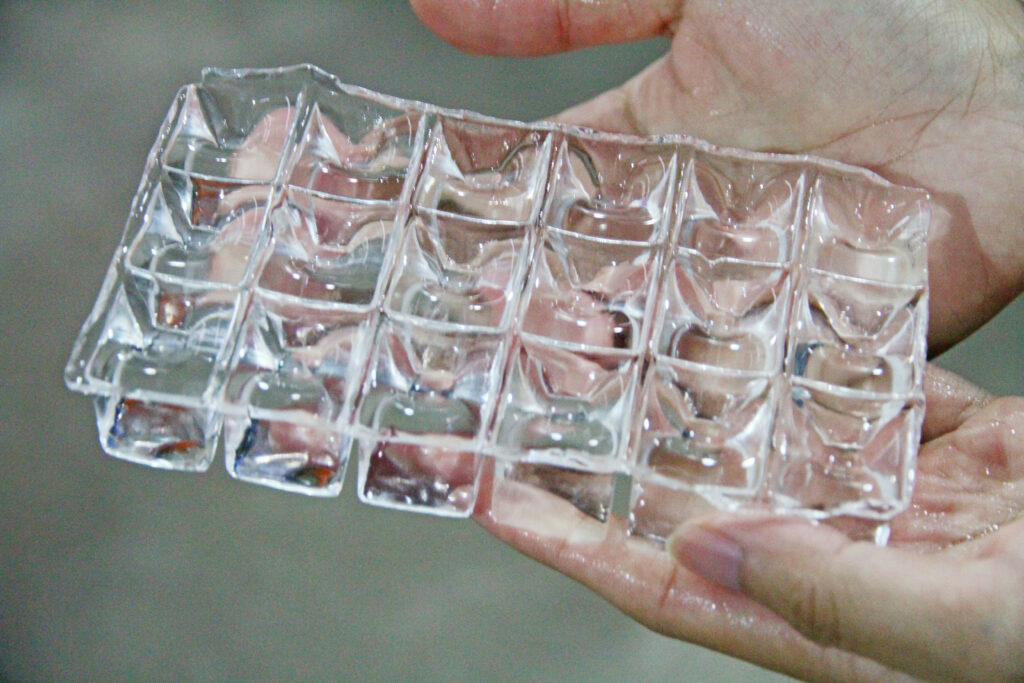

Industrial ice machines, also known as industrial icemakers, are indispensable for various businesses, including restaurants, hotels, supermarkets, and hospitals. They generate significant quantities of ice in diverse shapes and sizes, such as cube ice, flake ice, plate ice, and tube ice.

However, these machines require consistent cleaning and maintenance to guarantee peak performance and hygiene. This article delves into the proper and effective ways of cleaning and maintaining industrial ice making machines.

Why Should Clean & Maintain

The cost of cleaning and maintaining industrial ice making machines must be considered. Industrial ice machine applications in restaurants, hotels, supermarkets, and hospitals demand high-quality ice production. Unsanitary or inadequately maintaining machines can compromise the quality and safety of the ice produced, as well as the efficiency and longevity of the machines.

For instance, grime, scale, or mold can contaminate the ice, resulting in consumer health issues. Furthermore, these impurities can damage the machine components, reducing their cooling capacity and energy efficiency. Hence, adhering to a regular cleaning and maintenance schedule for industrial ice-making machines is crucial.

Daily Cleaning

Daily cleaning is the most fundamental and vital step in maintaining industrial ice-making machines’ cleanliness and sanitation. It involves wiping down the machine surfaces and sanitizing the ice storage bin. This prevents dust, dirt, or bacteria from accumulating on the machines and affecting ice quality. Daily cleaning also helps identify any potential problems or issues with the devices early on and enables corrective actions to be taken accordingly.

Tips

- Disconnect the power supply and water supply before cleaning.

- Utilize a soft cloth or sponge and a gentle detergent to wipe down the machines’ exterior surfaces. Refrain from using abrasive materials or harsh chemicals that could scratch or corrode the machines.

- Rinse the surfaces with clean water and thoroughly dry them with a clean towel.

- Sanitize the ice storage bin with a food-grade sanitizer following the manufacturer’s guidelines. Ensure the container is well-rinsed and dried before refilling it with ice.

- Clean the ice scoop or dispenser with hot water and soap, and store it in a clean container.

- Inspect the water filter and replace it if necessary.

Weekly and Monthly Cleaning

Besides daily cleaning, commercial ice making machines also require more comprehensive cleaning on a weekly or monthly basis, depending on usage and water quality.

It contains descaling the evaporator plates and cleaning the condenser coils. These components are responsible for freezing and cooling the water into ice, so they must be free from any scale or dirt buildup that could hinder their performance.

Tools

A descaling solution, a brush, a spray bottle, a bucket, a hose, a screwdriver, a vacuum cleaner, and a soft cloth.

Step-by-step Guide

- Disconnect the power supply and water supply before cleaning.

- Remove the machine’s front panel to access the evaporator plates and condenser coils.

- Mix the descaling solution with water per the manufacturer’s instructions, and fill a spray bottle.

- Apply the solution to the evaporator plates and let it sit for 15 minutes.

- Utilize a brush to scrub off any scale or residue from the plates.

- Rinse the plates with clean water using a hose or bucket.

- Repeat the process for the condenser coils.

- Use a vacuum cleaner to eliminate dust or dirt from the coils.

- Dry the plates and coils with a soft cloth.

- Reattach the machine’s front panel.

Sanitizing & Disinfecting

Sanitizing and disinfecting industrial ice making machines are also crucial in ensuring their hygiene and safety.

Sanitizing refers to reducing the number of harmful microorganisms on a surface to a safe level. In contrast, disinfecting involves eliminating all organisms on a surface. Sanitizing and disinfecting should be performed at least twice a year or more frequently if mandated by local regulations or standards.

Sanitizing and disinfecting involves using suitable cleaning products and carefully following the manufacturer’s instructions. Here are some specific steps on how to sanitize and disinfect industrial ice making machines:

Step-by-step Guide

- Disconnect the power supply and water supply before cleaning.

- Drain any remaining water or ice from the machine.

- Remove any removable parts, such as trays, baskets, or hoses, from the machine.

- Mix a sanitizing or disinfecting solution with water according to the manufacturer’s guidelines. You can use chlorine-based or quaternary ammonium products for this purpose. Ensure you wear gloves and eye protection when handling these products.

- Fill a bucket with the solution and immerse all removable parts in it for 10 minutes or as the manufacturer directs.

- Use a spray bottle to apply the solution onto the machine’s interior surfaces, such as the evaporator plates, the condenser coils, the ice storage bin, and the ice chute.

- Allow the solution to sit for 10 minutes or as the manufacturer directs.

- Rinse all parts and surfaces with clean water and thoroughly dry them with a clean towel.

- Reassemble the machine and reconnect the power and water supply.

The potential consequences of improper sanitizing and disinfecting can be severe and costly. For example, contaminated ice can cause food poisoning or other illnesses for consumers.

Moreover, dirty or moldy machines can violate health codes and regulations, resulting in fines or penalties. Therefore, sanitizing and disinfecting industrial ice-making machines regularly and properly is vital.

Troubleshooting Common Problems

Even with regular cleaning and maintenance, industrial ice-making machines may still need to improve their operation or quality. These issues include mold or slime buildup, low ice production, cloudy or soft ice, or unusual noises. Here are some tips on troubleshooting these problems:

Mold or Slime Buildup

This can be caused by poor water quality, insufficient sanitizing, and disinfecting, or high humidity.

To prevent this issue, use a water filter, sanitize and disinfect the machine frequently, and store the device in a cool and dry place. To address this problem, clean the appliance thoroughly with a disinfecting solution and replace any affected parts if necessary.

Low Ice Production

This can be caused by low water pressure, dirty water filters, scale buildup on evaporator plates or condenser coils, or faulty components.

To prevent this issue, check the water supply, replace the water filter regularly, periodically descale the plates and rings, and inspect the parts for any damage or wear. To address this problem, adjust the water pressure, clean or replace the filter, descale the plates and coils, or repair or replace any faulty components.

Cloudy or Soft Ice

This can be caused by high mineral content in the water, air bubbles, low refrigerant levels, or high ambient temperatures.

To prevent this issue, use a water filter, purge the air from the water line, check the refrigerant status, and store the machine in a cool place. To address this problem, install or replace a water filter, bleed the air from the water line, recharge the refrigerant level, or move the machine to a cooler location.

Unusual Noises

This can be caused by loose or broken parts, vibration of pipes or hoses, or improper installation.

To prevent this issue, tighten or secure loose parts, cushion any vibrating pipes or stockings, and install the machine according to the ice making machine manufacturer‘s instructions. To address this problem, replace broken parts, isolate vibrating pipes or hoses, or reinstall the appliance properly.

Professional Service and Repair

While some minor problems can be resolved using simple troubleshooting techniques, more complex issues or parts replacement may necessitate professional service and commercial ice machine repair.

Find a Professional Assistance

For instance, an industrial ice maker may require professional assistance if it experiences issues such as leaking water or refrigerant, constantly making loud noises, failing to produce ice, or displaying error codes on the control panel. In these cases, contacting a qualified service provider for assistance with your industrial ice making machine is advisable.

Tips

When selecting a service provider for industrial ice making machine repair, you should consider their experience and certifications.

Look for a provider with extensive knowledge and skills in repairing various industrial ice making machines, such as ball ice making machine, cube ice making machines, flake ice making machines, plate ice making machines, and tube ice making machines.

Also, seek a provider with relevant certifications from reputable organizations, such as NATE (North American Technician Excellence), EPA (Environmental Protection Agency), and ICEMA (International Commercial Ice Machine Association).

These certifications indicate that the provider has met certain quality and professional standards in their field.

Conclusion

Industrial ice making machines are valuable assets for businesses requiring large amounts of ice daily. However, proper cleaning and maintenance are necessary to ensure optimal performance and hygiene.

By following a regular cleaning and maintenance schedule, troubleshooting common problems, and seeking professional service and repair when needed, you can keep your industrial ice making machines running smoothly and efficiently for an extended period.