Ice plays a vital role in various industries from keeping drinks cool on a hot day to supplying essential medical services. And with the ever-growing demand for this refreshing necessity, the ice-making business can be a profitable and stable venture to explore.

Whether you’re a seasoned entrepreneur or just starting your journey into the business world, this guide will equip you with the essential steps to turn your ice-cold idea into a thriving reality. So, grab a metaphorical ice pack, and keep reading!

Identifying Demand

Market Research

Conducting thorough market research is a critical first step when starting an ice making business. Analyzing the demand for ice in the target market and identifying potential customers with specific ice needs help you grasp the requirements of different customer groups.

Don’t forget to study seasonal demand fluctuations for ice, which can vary based on factors such as weather patterns, local events, and industry-specific requirements.

Customer Segmentation

Use customer segmentation to optimize your production processes and efficiently allocate resources.

Moreover, recognizing seasonal demand fluctuations within each customer segment is crucial for maintaining adequate inventory levels throughout the year. This segmentation approach allows you to adapt their operations to meet varying demands during peak seasons or specific events.

Tip: Effective market research and customer segmentation are key elements in establishing a successful ice making business. By gaining insights into demand dynamics and customer preferences, entrepreneurs can position their ventures for long-term growth and profitability.

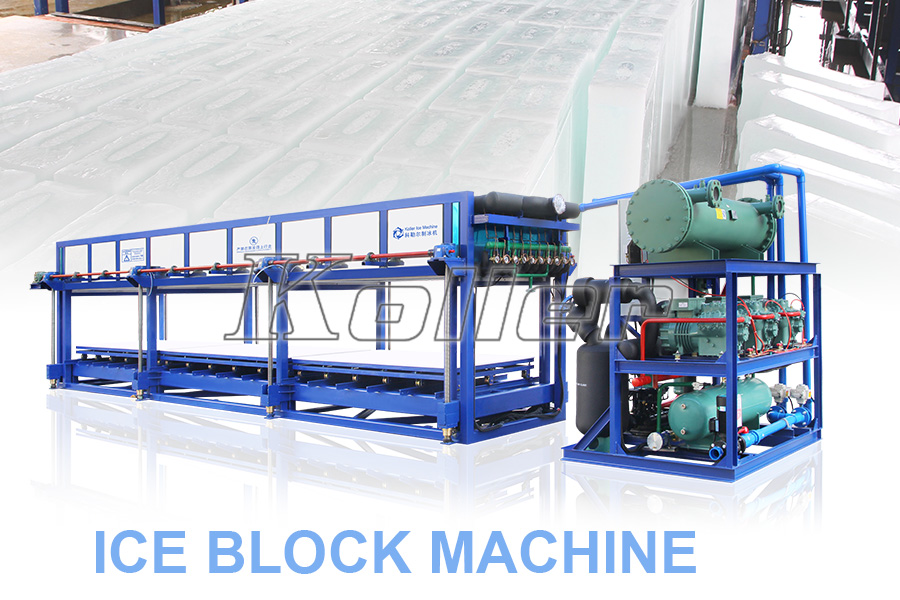

Buying Ice Making Equipment

Quality Ice Making Machine

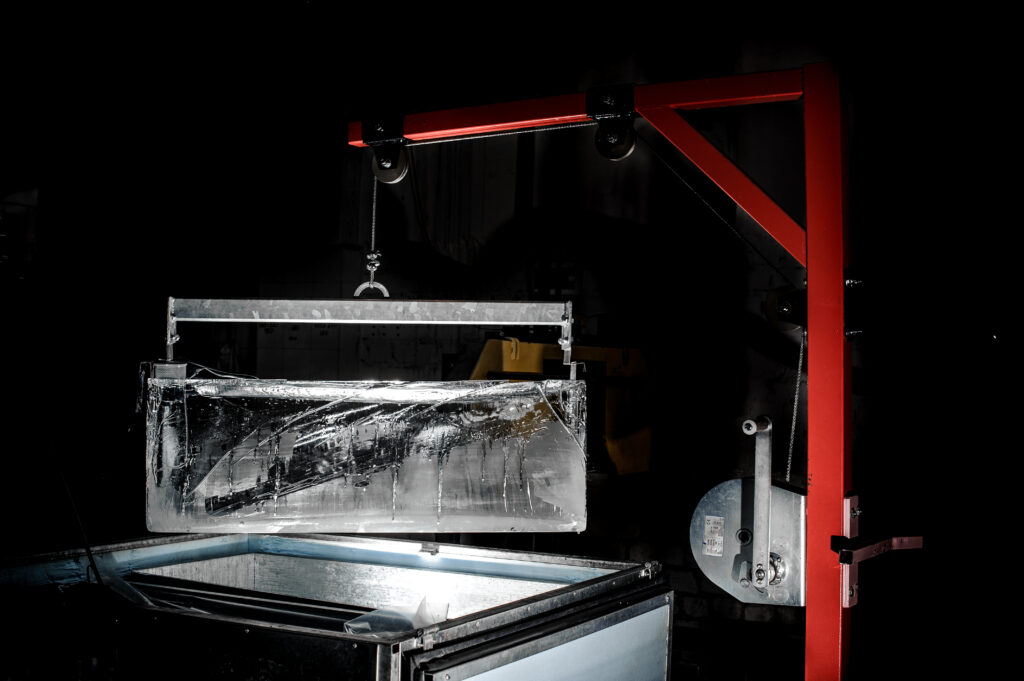

Investing in top-notch commercial or industrial ice machines and storage facilities is paramount for an ice making business.

When choosing ice production machinery, you should consider the specific requirements of their target market and customer segments. For instance, if there is a high demand for packaged ice in a particular area, investing in packaging equipment may be necessary to meet your consumers’ needs.

Tip: “The quality of your ice making equipment can significantly influence the success of your business. Investing in reliable machinery ensures consistent production and helps maintain high product standards. Buying direct from factories lowers your cash investment.”

Maintenance and Upkeep

Proper maintenance for the ice making machine isn’t just about extending that equipment’s lifetime, it’s also key for peak performance and efficiency.

This includes cleaning, lubrication, and inspection of components to identify any potential issues before they escalate.

Speaking of savings, having qualified pros on staff who know their way around this machinery can prevent a world of avoidable headaches. Skilled techs can promptly troubleshoot problems, minimize downtime, and make sure the whole production line is operating within safe parameters.

Legal Requirements

There’s a bunch of red tape you gotta cut through first if you want to keep things legit. We’re talking permits, licenses, the whole nine yards.

And that’s just the start – you also have to make sure you’re following all the environmental rules and regulations for an operation like this. If you want this ice making biz to chill long-term, ensuring a smooth operation from the start is essential.

Permits and Licenses

At the core, you’ll need to obtain the proper business licenses and permits related to food production, manufacturing, and commercial operations. The ice making process itself is heavily regulated when it comes to health codes, safety standards, and environmental compliance.

The licensing requirements can admittedly get granular and complex, varying from state to state and even locally. That’s why business owners must do their due diligence upfront.

Getting legalities lined up isn’t just about checking boxes, it’s about building credibility and trust with your customers, suppliers, and stakeholders.

Environmental Compliance

Environmental compliance is an integral aspect of running an ice making business responsibly. It encompasses practices such as waste disposal, energy efficiency, and adherence to environmental protection laws.

Prioritizing energy efficiency offers a dual benefit – it cuts operational costs while promoting sustainability.

Marketing Strategy

Crafting an airtight marketing blueprint is mission-critical for anyone who is looking to cut through the noise.

Targeting Customers

Whether it’s providing bulk ice supplies to hospitality businesses or catering to event organizers, a tailored marketing strategy ensures that the right message reaches the right audience.

Moreover, analyzing the startup expenses for an ice making business enables you to allocate resources. By evaluating the cost of acquiring new customers against potential returns, you will optimize your marketing budget while maximizing outreach efforts.

Branding and Promotion

Creating a strong brand identity involves developing a compelling brand story that resonates with target customers while highlighting unique selling propositions. Use online channels such as social media platforms and websites, along with offline methods like local events or partnerships.

Tip: “Crafting a targeted marketing strategy that resonates with specific customer segments is essential for establishing a strong presence in the competitive ice making industry.”

New Opportunities

Another thing you should take into consider before starting an ice or ice cube business is to observe those potential opportunities in the market.

These are some trending and creative marketing ideas:

- Focusing on commercial/industrial clients like construction sites, events, etc. rather than residential.

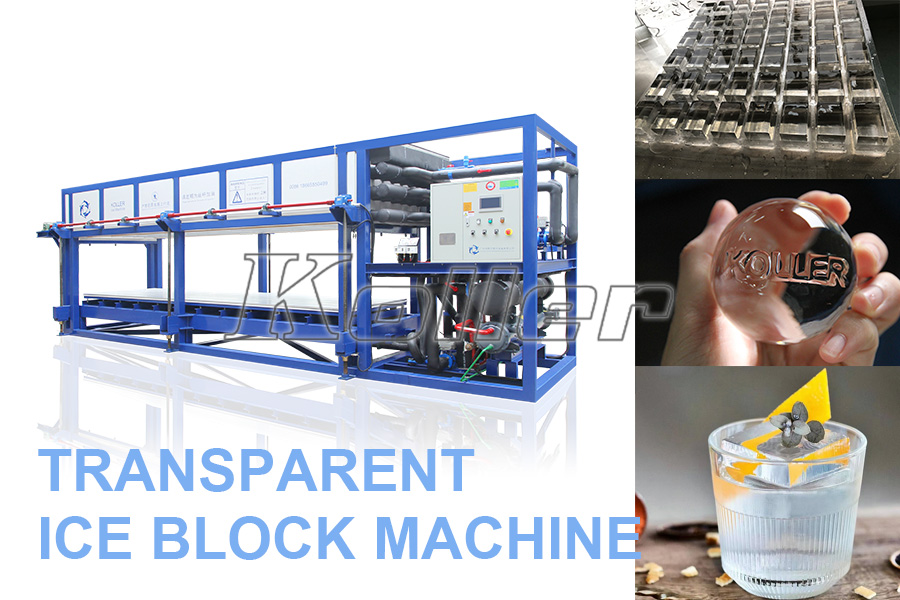

- Providing specialized types of ice like cube ice, flake ice or clear ice for mixed drinks.

- Capitalizing on a very local, niche market if there is huge demand in a particular area.

- Diversifying into selling other related products like bottled water.

The key is to come up with more creative ways to differentiate your ice making business and generate new revenue streams. With the right angle, you’ll find a new way to reform this traditional business.

Financial Viability

Cost Analysis

A comprehensive cost analysis involves evaluating the initial investment required to set up the business, including expenses related to acquiring ice making equipment, securing permits, and establishing operational facilities.

Additionally, assessing ongoing operational costs such as electricity, water, cleaning, and labor expenses is essential for developing a clear understanding of the financial commitments involved.

Profitability Projections

Estimating the potential profitability of an ice making business entails considering various factors. Market demand plays a significant role in determining the revenue-generating capacity of the business.

But revenue is just one side of the profit equation. You also have to meticulously account for all those pesky operating costs – equipment, facilities, labor, utilities, the whole nine yards. Sizing up those expenditures against your pricing strategy is crucial for projecting real bottom-line profits, not just top-line sales.

Final Thoughts

The path to launching a successful ice making operation may have its slippery spots, but tackle each phase with preparation and patience.

With meticulous planning and a commitment to quality products and service, your ice making business can capitalize on rising demand in a refreshingly profitable way.

Before long, you’ll be the one supplying the crowd-cooling refreshment that every good time depends on. What could be cooler than that?

FAQs about Starting an Ice Making Business

1. How Much Does it Cost to Start An Ice Business?

The startup costs for an ice making business can vary significantly depending on several factors. Some key expenses include:

- Commercial ice makers and freezer units

- Cold storage facilities or warehouse space

- Delivery trucks/vans

- Initial inventory of bags, supplies, etc.

- Legal/permitting fees

- Marketing and branding

On average, costs can range from a few thousand to several hundred thousand dollars.

2. Is Ice Making Business Profitable?

Yes, ice making businesses can be quite profitable when executed properly.

Profit margins for ice production and distribution range from 50% to over 80%. So every $1 in revenue could translate to $0.50 to $0.80 in profits after accounting for labor, utilities, maintenance and other operational expenses.

Of course, profitability hinges on factors like production volumes, operating efficiency, competition levels, and implementing smart pricing strategies. But overall, it offers promising earning potential for diligent entrepreneurs.

3. What Do I Need to Start An Ice Making Business?

Some essential requirements include:

- Commercial ice makers, ice machines and freezer storage units

- Warehouse, production, and storage space

- Bagging and other packaging equipment/supplies

- Refrigerated trucks or vans for distribution

- Permits/licenses for food production and sales

- EIN, business registration, insurance, etc.

- Funding or financing for startup costs

- Operational plan for staffing, production, deliveries

- Comprehensive marketing strategy

You’ll also need a keen understanding of your target market, demand levels, potential customer segments, competitive landscape and all costs associated with producing and delivering ice at scale. Proper planning and capitalization are critical first steps.

4. Where Can I Find Suppliers for Ice Making Equipment and Supplies?

Reputable suppliers for ice making equipment and supplies can be found through industry trade shows, online platforms, or by reaching out to established businesses in the field.