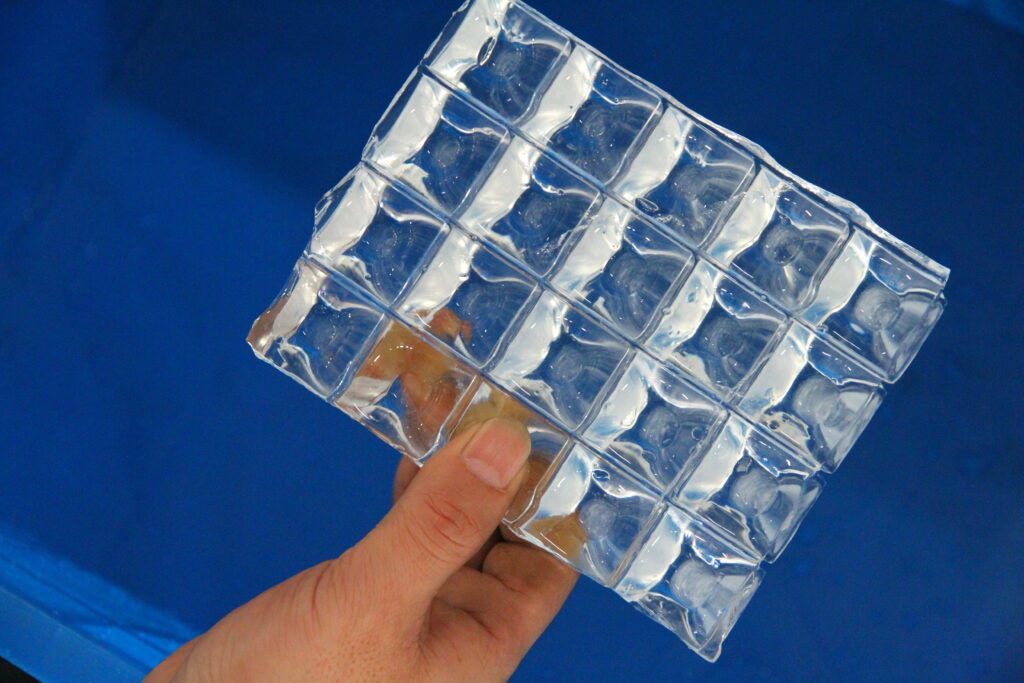

If you’re searching for a dependable, high-performance industrial ice machine to elevate your business, look no further than the cube ice maker.

As one of the most sought-after types of commercial ice making machines, cube ice making machines consistently produce pristine, solid, and uniformly shaped ice cubes, perfect for various industrial ice machine applications, such as beverages, food preservation, cooling, and ice sculptures.

If you’re searching for a high-quality cube ice making machine for sale, this guide will help you understand the benefits, features, and factors to consider when selecting.

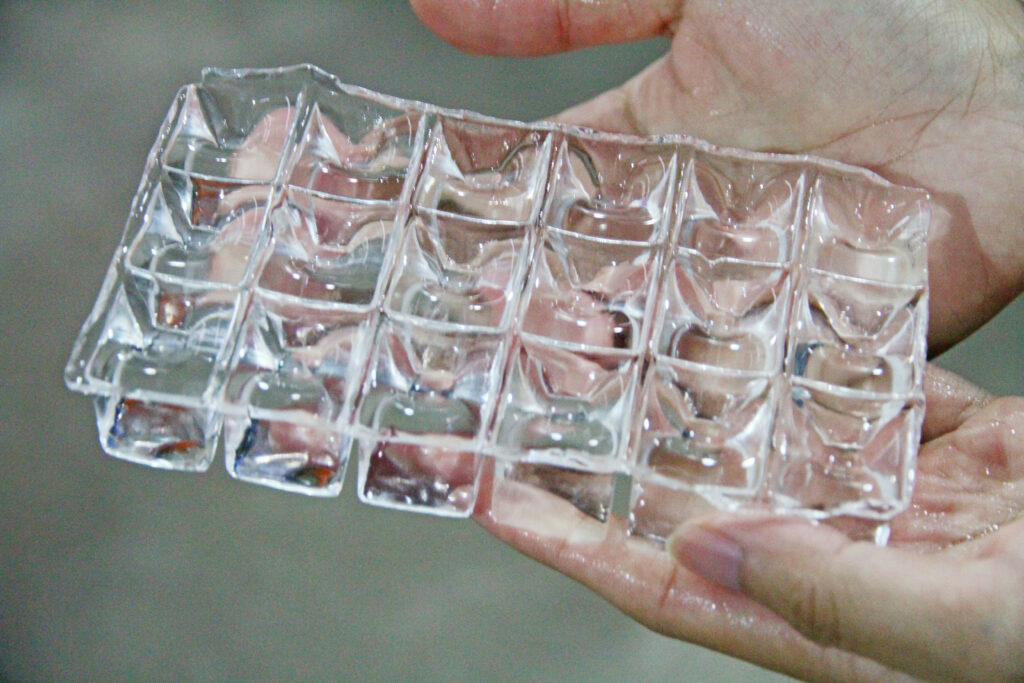

What is Cube Ice Making Machines?

Cube ice makers are versatile industrial ice machines that produce various sizes and shapes of ice cubes. These machines utilize a refrigeration system to freeze water into ice, then slice it into cubes using a matrix of sharp blades. The ice cubes are subsequently stored in a bin or dispenser until ready for use.

The Benefits of Cube Ice Makers

Cube ice makers boast numerous advantages for your business, including:

Consistent Ice Production

These machines generate a constant supply of ice throughout the day, ensuring you always have enough to meet demand.

Enhanced Productivity

Cube ice makers save you time and labor by eliminating manual ice tray filling and emptying or the need to purchase bagged ice from external sources.

Cost Efficiency

These machines lower operating expenses by using less water and electricity than other industrial ice makers while offering a longer lifespan and reduced maintenance costs.

Minimized Waste

Cube ice makers help minimize ice melting or clumping, resulting in less waste and more usable ice.

Factors to Consider When Choosing

When shopping for a cube ice maker, keep the following factors in mind:

Ice Production Capacity

Ice production capacity refers to the quantity of ice the machine can produce in 24 hours. Choose a device capable of meeting your peak demand with some additional buffer. Cube ice maker production capacities range from 20 kg to 1000 kg daily. When assessing your ice production needs, consider factors such as the size of your establishment, customer volume, and peak business hours to ensure you select an appropriate machine.

Ice Cube Size and Shape

The size and shape of the ice cube depend on your preferences and industrial ice machine applications. Cube ice makers can produce various sizes and shapes of ice cubes, such as entire cubes, half cubes, crescents, bullets, gourmet, and more. The size and shape of the ice cubes affect their melting rate, cooling effect, and appearance. To determine the ideal ice cube size and shape, evaluate the intended use of the ice, whether it’s for beverages, food preservation, or presentation purposes, and how quickly the ice needs to melt or maintain its form.

Storage Capacity

Storage capacity pertains to the quantity of ice the machine can store in its bin or dispenser. Choose a machine with enough storage capacity to hold the amount of ice you need at any given time. Cube ice maker storage capacities range from 10 kg to 500 kg. To choose the appropriate storage capacity, consider your daily ice usage and the frequency at which you’ll replenish the ice supply. Additionally, consider the available space in your establishment, as larger storage capacities may require more floor space or larger bins.

Energy Efficiency

Energy efficiency refers to the machine’s electricity consumption per kilogram of ice produced. When searching for an industrial icemaker for sale, consider models with high energy efficiency ratings and certifications to minimize your machine’s impact on the environment and your budget. Opt for a machine with a high energy efficiency rating to save on utility bills and reduce environmental impact. Cube ice maker energy efficiency varies depending on the model and brand.

Noise Level

This refers to the loudness of the machine during operation. Choose a low-noise level device to avoid disturbing customers and staff. The noise level of cube ice makers depends on the size and design of the machine. Remember that larger machines may generate more noise due to the increased power required for production. To mitigate noise levels, consider the installation location and any potential noise-reducing measures, such as insulation or soundproofing materials.

Ease of Maintenance

Ease of maintenance pertains to how easily the machine can be cleaned and serviced. Choose a device with simple, accessible components like filters, valves, and pumps that can be quickly removed and replaced. Also, opt for a machine with indicators or alarms that alert you to issues or maintenance needs. Regularly maintaining your ice machine ensures optimal performance and hygiene and can help extend its lifespan and reduce the likelihood of breakdowns. When selecting a device, look for models with user-friendly maintenance procedures and clear instructions provided by the ice making machine manufacturer, and consider the availability of replacement parts and service professionals in your area.

Installation

After purchasing the ideal ice making machine for sale, follow the recommended installation and maintenance procedures to ensure the engine operates efficiently and lasts for years.

Before installing your cube ice maker, prepare by following these steps:

- Select a suitable location for your machine, away from direct sunlight, heat sources, dust sources, and corrosive substances. Ensure adequate space for ventilation and drainage.

- Verify your machine’s electrical requirements, ensuring they match your power supply’s voltage, frequency, and amperage. You may need to install a dedicated circuit breaker or fuse for your machine.

- Check your machine’s water supply and drainage requirements. Ensure access to clean, potable water with adequate pressure and flow rate. You may need to install a water filter or softener to prevent scale buildup or contamination. Connect your machine to a drain pipe or floor drain with an air gap or backflow preventer to avoid water backflow or flooding.

- Assemble and test your machine according to the ice making machine manufacturer’s instructions. Adjust the ice cube size and shape, ice harvest time, and bin level sensor as needed. Flush the water system and sanitize the ice bin before using your machine.

Maintenance

To keep your cube ice maker in optimal condition and ensure peak performance, perform regular maintenance, such as:

Cleaning

Clean your machine at least once every six months or more frequently depending on water quality and usage. Follow the manufacturer’s instructions for cleaning the ice making system, ice bin, condenser, and exterior. You may need to use a specialized cleaner or sanitizer for your machine.

Sanitizing

Sanitize your machine at least once every six months or more frequently, depending on water quality and usage. Follow the manufacturer’s instructions for sanitizing the ice making system and bin. You may need to use a specialized sanitizer for your machine.

Ensuring Proper Ventilation

Ensure your machine has sufficient clearance and airflow to prevent overheating and reduce energy consumption. Avoid blocking the machine’s vents or fans with objects or dust, and clean the vents or fans regularly to remove dirt or debris.

Sustainability & Environmental Considerations

Cube ice makers are among the most energy-intensive appliances in a commercial kitchen, consuming significant amounts of water and electricity. This can negatively impact the environment and your bottom line. Therefore, consider the following sustainability and environmental factors when selecting and using your cube ice maker:

Opt for High-efficiency Models

Look for machines with high energy efficiency ratings or certifications, such as Energy Star or CE. These models can save up to 15% on electricity bills and reduce your carbon footprint by up to 10% compared to standard models.

Reduce Idle Time

Turn off or unplug your machine when not in use or when you have enough ice in storage. This can save up to 20% on electricity bills and reduce your carbon footprint by up to 15% compared to leaving your machine on continuously.

Perform Regular Maintenance

Follow the abovementioned maintenance tips to keep your machine in good condition and ensure optimal performance. This can save up to 10% on electricity bills and reduce your carbon footprint by up to 5% compared to neglecting your machine.

Conclusion

Cube ice makers are ideal for businesses seeking a dependable and efficient industrial ice machine, producing consistent, high-quality ice cubes for various applications.

When selecting a cube ice maker, consider factors like production capacity, size, shape, storage, energy efficiency, noise level, and ease of maintenance.

Ensure proper installation and maintenance for optimal operation and longevity, and adopt sustainability measures to reduce environmental and budgetary impacts.

If you’re in the market for a premium cube ice maker, contact us for a range of options tailored to your needs. We also provide other industrial ice machines, such as ball ice making machines, flake ice making machines, plate ice making machines, and tube ice making machines.